DISTRIBUTION: GTA Members – primary contact list. Please circulate to all appropriate internal parties

Table of Contents

1. Issue

Grain Trading Standards to apply for the 2025/26 season as of 1 August 2025, are now available on the GTA website.

2. Background

GTA Member Updates No.2 of 25 and No.4 of 25 sought feedback from industry on potential changes to Trading Standards (Standards) for the coming 2025/26 season. Feedback was received from a range of industry sectors on the proposed changes and a range of other issues.

The GTA Trading Standards Committee (Committee) met in late 2024 and through 2025 on several occasions and reviewed feedback from industry. The Committee recommended changes to the GTA Board, and the Board has adopted recommendations as appropriate.

This document lists:

All 2025/26 Standards and industry submissions received during 2025 on proposed Standards can be viewed on the GTA website at https://graintrade.org.au/grain-trading-standards

3. Agreed Changes for 2025/26

Unless otherwise noted in the following, industry did not object to the list of changes advised in the second round calling for industry submissions, as listed below.

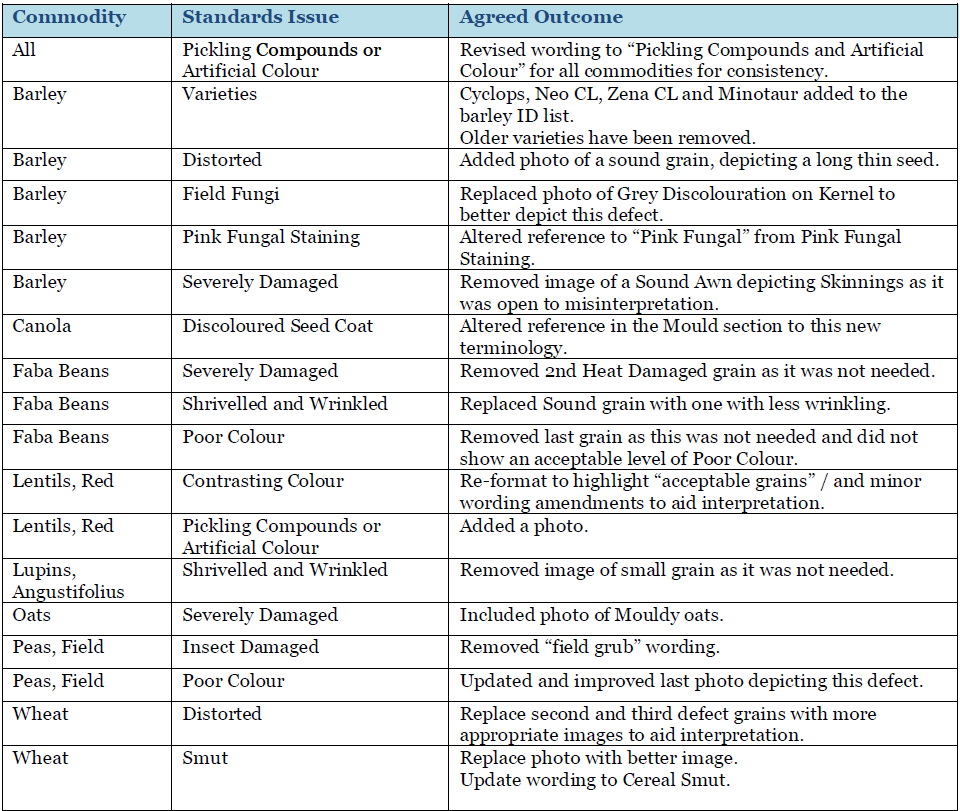

3.1 Agreed Change: Visual Recognition Standards Guide – all commodities

As advised during 2025 the existing Visual Recognition Standards Guide (VRSG) produced by GTA was being reviewed for the commodities listed in that document.

General changes have been made to the document in many instances to provide greater clarity and aid interpretation. Changes are outlined in the table below.

The 2025/26 version of the VRSG can be obtained here

3.2 Agreed Change: Minor Wording Changes & Other Issues – various commodities

Minor changes to wording in all Standards charts and Standards booklets have occurred. These changes were made to refer to the latest versions of reference material available to assist industry implementation of Standards, including:

3.3 Agreed Change: Varietal Master List – Wheat, Barley, Oats

As in previous seasons, the Varietal Master List for the above commodities has been revised following receipt of relevant changes from the industry sector responsible for the classification of those grain varieties. For all commodities (except mung beans) GTA has:

3.4 Agreed Change: Procedures – All pulse commodities except Mung Beans

Industry was advised during 2024 that as GTA now develops the Pulse Trading Standards (except mung beans) on behalf of industry, the Committee had commenced revising the Pulse Standards Booklet with the intention of making the Booklet appear as per cereals. While some procedures were revised for the 2024/25 Standards Booklet, several remained to be done, and the Committee has developed a number of the remaining procedures during 2025.

The revised Procedures are published in the Pulse Trading Standards Booklet for 2025/26. The remaining procedures will be developed in the 2026/27 Standards Booklet.

3.5 Agreed Change: Barley1 and Barley2 Grade Names – Barley

In developing the 2024/25 Standards, industry was advised:

Therefore, in the 2024/25 Barley Standards where there was a reference to Barley1 and Barley2 the following words for clarification purposes only were added:

Barley1 and Barley2 Grades (Commonly known within industry as BAR1 and BAR2).

Industry was also advised that during development of the 2025/2026 Trading Standards, a more formal change of the Grade names from Barley1 and Barley2 to BAR1 and BAR2 respectively would occur.

The Committee has agreed to this change for the 2025/26 season.

3.6 Agreed Change: Screen Size – Fenugreek

The Fenugreek Standards reference a screen and include “all Fenugreek seed material falling through the screen” in the Total Defective category. However, despite previous attempts for information, an appropriate screen size could not be obtained for reference in the Standard to assist industry interpretation.

The Committee received advice that a 1.4mm slotted screen is appropriate, hence it was agreed to reference this screen in the 2025/26 Fenugreek Standards in the following areas:

4.1 Agreed Change 2026/27: AGP1 – Wheat

The current specification for Falling Number (FN) for AGP1 is a minimum of 200 seconds. A submission was received indicating there is no market demand for AGP1 that has a FN of below 250 seconds due to the negative quality of the resulting flour. The Committee noted that in general, where the average FN of wheat stacks are below 250 seconds, the grain goes to the Feed market.

The submission requested the Committee to consider a change in FN for AGP1 from a minimum of 200 seconds to 250 seconds. The main intent of the change was to bring AGP1 into alignment with other off grade milling wheats for FN.

The Committee noted that the use of AGP1 had changed over time and AGP1 below 250 seconds was generally significantly discounted. Discussion also arose on the potential to also change other AGP1 parameters to those of AUH2, however the Committee considered there was no need at present.

The Committee agreed to a change in the minimum FN for AGP1 from 200 seconds to 250 seconds, to apply for the 2026/27 season.

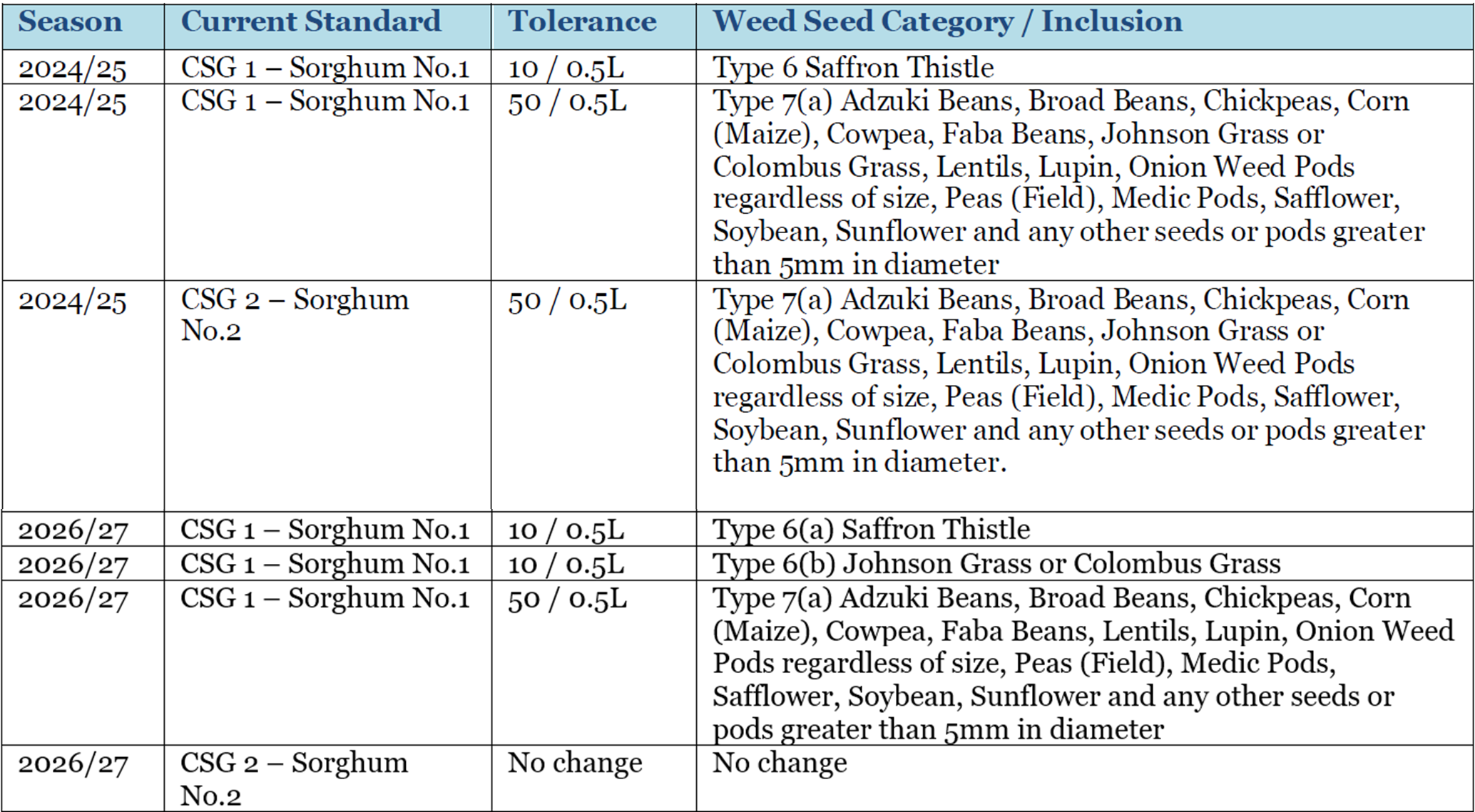

4.2 Agreed Change 2026/27: Johnson Grass / Columbus Grass Tolerance – Sorghum

During 2025 industry was advised of various options to alter the tolerance for Johnson Grass / Columbus Grass in sorghum Trading Standards. The driver for a potential change was a submission received from industry seeking a change in the current tolerance as the current tolerance of 50 seeds / 0.5L significantly exceeds the tolerance required by a major market for Australian sorghum. The difference makes sourcing grain and supplying the market difficult.

Submissions on this subject were received calling for the limit for Johnson Grass/Columbus Grass be reduced from 50 to 10 seeds per half litre, with others seeking a reduction for Sorghum No. 1 only.

The Committee noted:

Following discussion, the Committee agreed to the following:

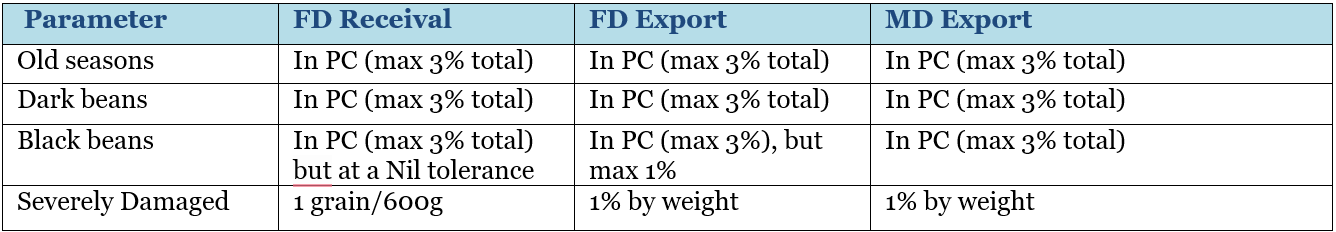

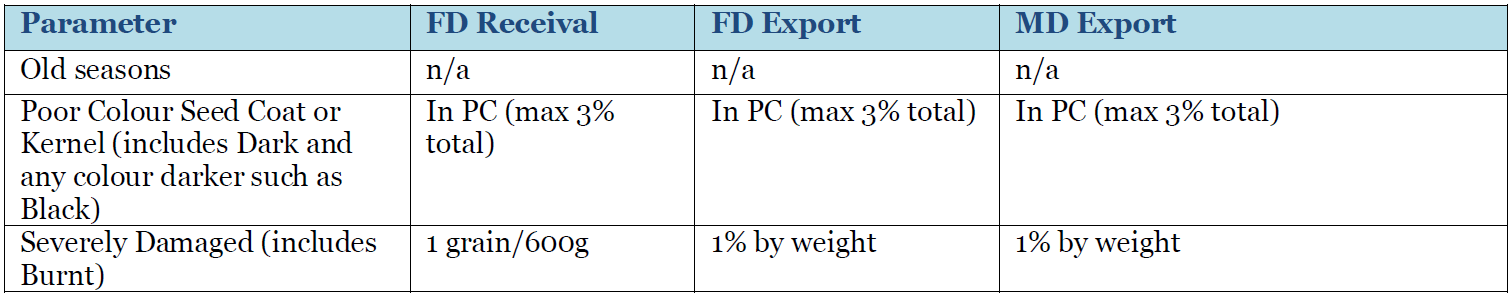

4.3 Agreed Change 2026/27: Colour References – Broad Beans

In the first call for industry submissions industry was advised the current Broad Bean Standards have various references to colour, including evergreens, old seasons, dark beans, black beans and beans that are “distinctly off colour from the characteristic colour of the predominating class”.

A review of those various references has occurred, and the findings of the Committee are outlined below.

In current Standards:

The Committee discussed this issue and determined:

Following discussion, the Committee agreed to seek industry comments on the following change for 2026/27:

Old Seasons – Remove and let it be placed as a contract term if needed.

Dark – Include in Poor Colour with no separate maximum tolerance.

Black – As per the faba bean definition, refer to Burnt which is included in Severely Damaged or under Poor Colour.

For clarity, the tolerances that would apply are as follows:

4.4 Agreed Change 2026/27: Severely Damaged – Various Split Pulse Standards

A submission was received from industry seeking to decrease the tolerance for Severely Damaged from 1% by weight to 0.5% by weight for all “No.1” Split Export Standards. The Committee discussed the issue for the following Split product Standards:

The Committee considered the request and agreed to the change for the 2026/27 season on the basis of:

4.5 Agreed Change 2026/27: Total Defective – Kabuli Export Machine Dressed Standards

A submission was received from industry seeking to increase the tolerance for Total Defective from 2% by weight to 3% by weight for all No.1 Kabuli Machine Dressed Export Standards. The Committee discussed the issue for the following Standards:

The Committee considered the request and agreed to the change for the 2026/27 season on the basis of:

4.6 Agreed Change 2026/27: Total Defective – Albus Lupin Minimum Export Machine Dressed Standard

A submission was received from industry seeking to increase the tolerance for Total Defective from 2% by weight to 3% by weight for 8.2.3 No.1 Albus Lupin Minimum Export Machine Dressed Standard.

The Committee considered the request and agreed to the change for the 2026/27 season on the basis of:

5. Issues for Further Ongoing Consideration

5.1 Further Research: Vacuum Sampling of Road Trucks – All Commodities

The project to review the appropriateness of sampling systems on receival from road trucks has completed its initial phase. Based on initial findings, further research is required and is being progressed during 2025.

Industry will be advised of findings in due course.

5.2 Further Research: SFW1 – Wheat

Industry was advised in 2020 of a submission requesting a change in the tolerances for a range of defective grain types in the SFW1 grade. That submission in total was not supported and no changes to the tolerances occurred. Since that time, a further submission requesting changes to Field Fungi and Severely Damaged grains only was received. The submission requested changes as follows:

Discussion by the Committee on this topic included:

The Committee continues consultation on the proposed changes with the stockfeed sector. Industry will be advised of the findings during 2025.

6. Matters where no further action is required

6.1 No change: Defect Assessment Method – All commodities

A submission was received from industry noting that percentage by count for defects is considered too time consuming for use as a field method for grain assessment. As a consequence, the Trading Standards has historically used percentage by weight for assessment of defects.

The submission stated that new visual assessment technology can assess defects as a percentage by count and the conversion to weight is an unnecessary added step. The submission requested the Committee consider applying a percentage by count for future available technology when assessing defects.

The Committee noted:

As these issues need to be considered in future when technology is more readily available or impending for all commodities, no change is warranted to existing Standards.

6.2 No change: Kabuli Chickpeas – Sizing

The current Kabuli Chickpea Standards refers to small as 5-6mm in diameter and large as greater than 6mm in diameter. The Committee had been advised that there may be a difference in the view of breeders/classification of Kabuli Chickpeas, with any Kabuli less than 8mm considered small.

The Committee has determined the marketing of chickpeas is different than breeding and the sizing differences are valid.

Therefore, no change to Standards has been made.

Member Update No. 23 of 2025 – GTA Board Appointments 2025-2026

29 October 2025

Member Update No. 19 of 2025 – GTA Annual General Meeting 2025 Notice

26 September 2025

Stay updated on industry news and events. Subscribe now for exclusive updates and insights!

Self Regulatory Framework

NEWS

Self Regulatory Framework

NWPGP

NEWS

Events

Street Address

Level 7

12 O'Connell Street

Sydney NSW 2000

Postal Address

PO Box R1829

Royal Exchange

Sydney NSW 1225

Street Address

Level 7

12 O'Connell Street

Sydney NSW 2000

Postal Address

PO Box R1829

Royal Exchange

Sydney NSW 1225